Trends of Developing Milk Alternatives

and our Cheese Alternative "Styrino"

Marinfood ltd, Shingo Uoi, Yoshihiro Kobayashi, and Shiori Seo

1. About "Styrino"

"Styrino" is our original brand name of cheese alternative products that our company developed. The name was derived from the combination of two Greek words "styno" which means future or progressive, and "tyri," which means cheese. We named this product "Styrino" so that it is going to be a future cheese. In this chapter, we introduce you to the history of this cheese alternative, its domestic and international markets, the characteristics of Styrino and the current conditions and future prospects.

The alternative cheese products that include our Styrino are called "cheese alternative," "imitation cheese," "analog cheese," and "artificial cheese."In this chapter, we will use the word "cheese alternative," for the cheese alternative products in general, and "Styrino" for our original cheese alternative product. For convenience sake, they are also called "plant-based cheese" by media and the distribution industry, however, they do not correspond with cheese that are either natural cheese or processed cheese that are designated in the Ordinance of Component Rules and Regulations for Milk and Milk Products within the Food Sanitation Law.

2 The History of Cheese Alternative

The history of cheese is old, and it is called one of the oldest in the history of processed foods. However, when, where, and how humans started to make cheese is not certain. As milk is necessary to make cheese, its history supposedly can be traced back to B.C. 6000 when people started to domesticate sheep and goats. It is said that cheese making started by accidentally finding that milk that was kept in a bag that was made of a stomach of a ruminant separated into curd and whey by an enzyme called rennet. Whatever that may be, a number of natural cheese types were made based on the climate and history of the lands.

However, natural cheese has a limitation in its storage period, and changes its flavor from time to time. With the wish to keep it longer, people developed the new types of cheese. Processed cheese was made from natural cheese. In 1911, two Swiss - Walter Gerber and Fritz Stettler - succeeded in producing processed cheese using molten salt. Then the production of cheese started in America soon afterwards. In the 1930s good quality molten salt was started to be sold, and quality processed cheese was beginning to be made in various countries.

The next challenge of humans after they satisfied their desires about quality, flavor and preservation was about cost. The natural cheese is made with labor and time and requires a significant cost in production, preservation and distribution. The cost of making processed cheese that is made from natural cheese as a matter of course depends on the cost of natural cheese. In order to solve this issue, we have developed our cheese alternative. Cheese alternative was introduced in 1970s in America then spread to England, Sweden, France, Germany, Belgium, Switzerland and Australia. Its types are mainly cheddar, mozzarella and Monterey Jack, which are modeled after natural cheese, and its use was slices for pizza and hamburgers that were leaning toward cost reduction. In Japan when the market price of the cheese ingredient went up, alternative cheese was produced and sold by several companies, and when the price went down, it disappeared from the market. Our Styrino, however, has targeted consumers who are more health conscious, and it has lead the growth of the cheese alternative market from the late 2000s to now, by emphasizing its significant cholesterol reduction.

3 The significance of Cheese Alternative and two approaches

In Japan under the Ordinance of Component Rules and Regulations for Milk and Milk Products, natural cheese is defined as made from milk, butter milk or cream, coagulated into curd then whey is removed, and then matured. Milk is mainly cow's milk, but buffalo, goat or sheep milk is also used. Aging also varies the flavor and characteristics and they also depend on the lactic acid bacterium, notwithstanding white mold, blue mold and linen bacteria that is added. When you take a look at cheese from component perspective, it is divided into Milk protein, milk fat, water and other. The ordinance defines processed cheese to be made from natural cheese, pulverized, added heat, melted then emulsified, so the components do not differ a lot from natural cheese. On the other hand, cheese alternative has a lot of kinds and shapes, yet it does not have a designated definition as natural cheese or processed cheese. It can imitate the constituent, looks, characteristics (melting or stretching) and flavor of cheese, and when it has the specific quality of the targeted cheese, you may call it a cheese alternative. You may not pursue the level of completion in its flavor and structure or preservative quality, and call it cheese alternative for that home-made stuff made from soy milk, lemon water and vinegar, because of your own orientation toward health or your child's allergic conditions. Below is the objective and advantage in making cheese alternative.

・By replacing milk fat with vegetable oil and milk protein with plant protein or processed starch, you can reduce the production cost.

・While manufacturing natural cheese requires a number of large scale facilities, cheese alternative takes a lesser amount of cost in manufacturing, as the process is mainly focused on mixing the ingredients and agitating those.

・When making natural cheese, the process starts from collecting and pasteurizing milk to aging that can take up to years. In the meanwhile, it is possible to manufacture cheese alternative in only several days if you only have the necessary ingredients to mix, agitate and cool.

・ By differentiating ingredients as per constituents, melting quality, flavor and nutrient fortification that you would like to pursue, customization is quite easy and possible.

When you talk about manufacturing cheese alternative on the industrial level, generally speaking, the main method of producing is to replacing either, both or partly the milk protein and milk fat with vegetable protein and vegetable fat.

There are two basic approaches in developing cheese alternative. One is a method that you replace the part of the component of cheese with alternative ingredient. In this case, the knowledge and technology about milk protein and emulsification based on the scientific theory of making natural and processed cheese is utilized and the end product is also very similar to cheese. The other method is to make a block or paste-like object that is made of starch or plant protein then afterwards to add stabilizer, thickener or flavor ingredient to bring about a melting or stretching quality. When you do not use milk ingredient, the scientific theory of cheese making is not utilized, and the result mainly is based on the ingredients and the trial and error. The latter can be very different from cheese compared with the former in its flavor and texture. However, it can also attain a characteristic that it does not contain lactose ingredient (milk allergen) that has not been possible for the real cheese.

Our company succeeded in developing products in two above approaches. The above product that imitated cheese in its scientific constituent is sold under the category of Styrino (the actual product can be named differently), and the latter product that does not use animal ingredient is sold as vegan shred.

4 The Condition of Cheese Alternative Abroad

As to cheese alternative, the statistics are not collected so the accurate number is not certain, but while the cheese market in the world is 20 million ton/year, the cheese alternative market is speculated to be about 1.5 million ton/year. As far as our research, the shapes of cheese alternative in the world are varied and they include shred, slice, block and powder. Taking a look at a shred type that is used for heated dishes such as pizza, although it may not include cheese in its ingredient, shredded cheese alternative products are sometimes named as "mozzarella type" or "cheddar type." However, the flavor of those cheese alternatives, many of which are vegan, are made with soy protein, yeast extract or flavoring agent, and they are not necessarily close to cheese. Talking about melting quality, many of them do not have that either compared to cheese alternative made in Japan, including our product. Many consumers abroad look for cheese alternative based on their religious, philosophical or lifestyle beliefs, so that a lot of products put forward concept rather than similarity with cheese in its flavor and texture. However, the recognition is huge by far and one grocery store in America (Figure 1) displays cheese alternative, next to plant-based mayonnaise alternative and plant-based meat alternative.

Figure 1.one grocery store in America

5 The Current Condition of Cheese Alternative in Japan

Cheese alternative products in Japan are either produced from the beginning domestically or the cheese alternative block made abroad is imported, processed, packaged and sold domestically. The amount of consumption of cheese in Japan is about 350 thousand ton/year, while the number of cheese alternative is about 7 thousand ton/year (Marinfood speculation) and its spread is less compared to Western countries. Its types are varied, and some products for home-use pursue health benefit including our Styrino, some imitates specific cheese products such as camembert or mozzarella, some market their products as soy products. The shapes are mainly shred and slice. In Japan, it has not yet been showcased as the exclusive display space for plant-based food products, and they are displayed next to natural cheese and processed cheese under milk products. For industrial use, the main use is for shred used for pizza, but a cheese block type or paste type imitating cream cheese does exist.

6 The Details about our Styrino and its Characteristics

In order that cheese alternative products are used as a substitute of cheese, they have to hold some of the characteristics of cheese in its appearance, flavor and texture. The shapes of cheese products in the market are varied and many of them are processed in shapes of shred, slice, baby (a bite-sized block), portion and dice. So first of all cheese alternative products should be also processed in the above shapes and in white to yellow colors. Next, the flavor is required to be close to those familiar cheese products, including Gouda, cheddar, camembert and mozzarella. The appearance when it is heated also affects our senses. Many cheese products are solid shapes but shredded cheese for pizza and sliced cheese melt and burn in gold color. Cheese alternative products should also resemble these above characteristics of cheese, including the melting and burning quality, how the oil shows up after heated and also the stretching quality of cheese. In our pursuit of realizing the texture of cheese, our Styrino as said above is created with its constituent of protein, fat and water. Without modifying this base composition, by replacing milk fat with vegetable fat, it has attained the cheese texture.

The nucleus of cheese texture is rennet casein. Rennet casein is a part of milk protein and it is included in cheese. Not only Styrino but also many cheese alternative products are made with rennet casein. One of the roles of rennet casein in Styrino is to emulsify water and fat, similarly to processed cheese. With the presence of molten salt, rennet casein changes to the amphiphilic structure that is both hydrophilic and hydrophobic and so it has an emulsifying function. That is how, in Styrino, with the addition of molten salt, rennet casein emulsifies water and fat. Besides rennet casein influences a lot in stiffening the material of Styrino after cooling. The higher the content percentage of rennet casein in the ingredient, the Styrino material gets harder after cooling. In addition the rennet casein affects the flavor, texture and melting quality for heated dishes such as pizza. In processed cheese the rennet casein constructs the network organization and shapes its body, which is same with the case of Styrino. That is why it is indispensable in using rennet casein in realizing the texture and melting quality that is unique in cheese. However rennet casein is part of milk product and the price fluctuation is huge and comparatively expensive. You should adjust the amount of usage depending on your purpose. As far as our research goes by collecting cheese alternative from abroad, it seems a lot of those products use palm oil and coconut oil to replace milk fat. Our Styrino also uses these fats. The characteristics of these oils are that their melting points are high. When the melting point of the fat is low, the material of the cheese alternative, after cooling, is still soft and does not have the hardness that is necessary in processing to shreds or diced cuts. The percentage of fat can be similar to those of milk fat in cheese. In the case of palm oil that has a higher melting point, it contributes to the hardening of the material so when used in low percentage, the material gets softened and when used in large amount it contributes to the stickiness of the material and it is not suitable for processing.

For the purpose of ingredient cost reduction, many cheese alternative products are added with processed starch. Processed starch includes many kinds including oxidized starch and hydroxypropylated starch, but the end texture of Styrino depends on the types of starch, so the choice is important. The advantage in using processed starch in Styrino is its rise in the material stiffening and thickening. As the processed starch is used to replace part of the rennet casein, it has to suppress the lowering of the material hardening. The stickiness of the processed starch increases the elastic force of the material and improves the conserving quality in its procession and distribution. However some processed starch affects negatively the rise in its material stickiness and its melting quality when heated, and so the types and the amount of the blending requires caution.

As said above, the composition and the end texture of Styrino resembles natural cheese, but the process of production is very different. Natural cheese goes through pasteurization, addition of rennet and lactic acid bacterium, cutting, agitation and heating, removal of whey, mold packing and compression, addition of salt and maturing. For making Styrino, milk protein, fat, water and other ingredients are blended in an emulsifying pot, agitated, heated and emulsified then cooled after filling. The process is similar to the emulsifying process of making processed cheese using natural cheese using molten salt. However when the order of the blending of ingredient is different, the same amount of ingredient and percentage brings about a completely different object. The Styrino after emulsified is liquid so the molding is easy. They are molded into blocks and slices and the blocks are processed in shreds and dices after cooling.

Although the production facility of Styrino is similar to that of processed cheese, the processing condition of heating in the emulsifying pot is unique. Most of the processed cheese including baby cheese and diced cheese is manufactured targeting the room temperature consumption, but Styrino is manufactured so that it will be heated to serve. It means that Styrino has to offer the melting quality similar to natural cheese that processed cheese does not have. In so doing, the heated agitation process in the emulsifying pot is utilizing its unique emulsifying process that is contributing to the texture close to natural cheese.

6.1 The Reduction of the Content of Cholesterol

One of the characteristics of Styrino is that the content of the cholesterol is reduced compared to cheese. According to the Japan Food Standard Composition Table 2015, while Gouda cheese contains 83 mg per 100g cholesterol, a representative Styrino material within the many kinds that have been developed to suit the consumer needs, contains 4mg per 100g cholesterol. It is because Styrino mainly uses vegetable fat instead of milk fat as its ingredient. Ingredients of Styrino include some that derive from milk and many of them are rennet casein or skim milk powder that does not contain fat. A tiny amount of cheese powder that is added for flavoring purpose contains a small amount of milk fat. Food Trend Research held by Japan Policy Finance Corporation 2019 indicates that the top consumer food trend is health (46.6%) and it is highest in its number. One of our Styrino products named "Cholesterol 95% Off Healthy Shred" is increasing its sales year by year, led by this trend toward health concerns.

6.2 The Reduction in the Content of Fat

Figure 3.Fat 30% Reduced Healthy Shred 300 g

One of the lineups of Styrino is "Fat 30% Off Healthy Shred"(Figure 3). This number 30% off is the reduction rate that compares with Gouda cheese. While gouda cheese contains 29.0g/100g fat (Japan Food Standard Composition Table 2015), "Fat 30% Off Healthy Shred" reduced its fat content to 18.g/100g, its calories to 265 kcal/100g, which is 25% off compared with gouda cheese (380kcal/100g: Japan Food Standard Composition Table 2015). So not only reducing cost and cholesterol as other existent Styrino products, "Fat 30% Off Healthy Shred" reduced fat and calories. The main source of calories in Styrino is vegetable fat (about 900 kcal/100g). Our company succeeded in developing cheese alternative that reduced both fat and calories, by searching the ingredients and manufacturing processes that enable the realization of cheese texture despite its reduced fat content.

6.3 Mozzarella Type

Generally speaking, cheese alternative products including our Styrino may melt like cheese when heated, but they do not have a strong stretching quality like mozzarella. Some products named "Analog Mozzarella" melts when produced fresh, but it is very difficult to maintain its stretching quality for several months that is required as industrial marketing base. Our company succeeded in developing Styrino that models after mozzarella, naming it "Mozzarino"(Figure 4 and 5) in the spring 2020.

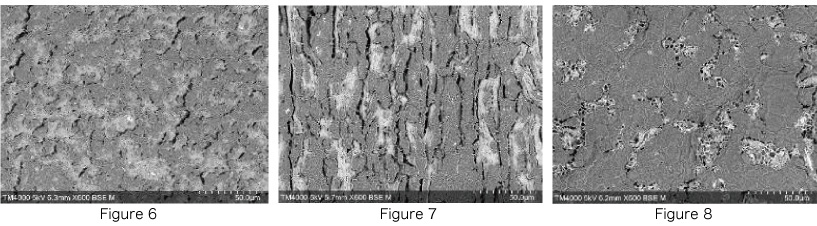

The most important element that enables the stretching quality of mozzarella cheese is milk protein casein. Casein exists forming granular casein micelles within the milk ingredient in cheese. It clumps together with the help of lactic acid bacterium and rennet that is enzyme, and forms a network structure with each other. In mozzarella cheese, the method called pasta filata that kneads the cheese in hot water is used to gives the cheese its fibrous structure. When the fibrous structure of mozzarella is squeezed out to one direction, it is called string cheese, which tears apart. Our Mozzarino is made using the same composition and method that model after this mozzarella cheese. We made an observation of its material structure to study its stretching structure with a scanning type electron microscope (Figure 6 ~8).

Figure 6 is melting slice cheese, and figure 7 is string cheese, and figure 8 is mozzarino (all of them are our company's product). Melting slice does not have a strong fibrous structure or a directive structure.

The string cheese undergoes a manufacturing process of a kneading treatment in hot water, so it has filamentous fibrous structures in its cross section and they form a one-direction line (Figure 7). The mozzarino does not have a directive structure, but a network structure, which contributes to stretching and melting quality.

Figure 6: The cross section view of the melting slice cheese (observing temperature -20℃, scale factor 600 times).

Figure 7: The cross section view of the string cheese (observing temperature -20℃, scale factor 600 times).

Figure 8: The cross section view of the mozzarino cheese (observing temperature -20℃, scale factor 600 times).

Figure 5.The stretching quality of mozzarella cheese

6.4 Completely Milk-free Vegan

In abroad there are increasing number of vegetarians and vegans that prefer plant-based products over animal-derived products not only in food but overall belongings, and flexitarians who choose plant-based foods several days a week. The world trend is gradually shifting to lifestyles that prefer plant-based food. Because of this trend, people are starting to choose plant-based food for health in spite of the rather small recognition of vegans. It started with plant-based milk including almond milk and coconut milk, to soy yoghurt, to plant-based cheese and other milk products.

As said above, our company succeeded in producing cheese alternative that completely replaced milk ingredients with plant-based ingredient, which is called vegan shred (Figure 9). This vegan shred does not use animal ingredients or 28 known allergenic ingredients, so it is supported by people who have allergic reactions from not only milk ingredients but also soy, wheat, and almond. (However it is produced on the same manufacturing line with milk products).

Our vegan shred is produced using plant-based ingredients that are completely different from milk products, and yet has a texture that is similar to cheese. Also it has the basic components that follow cheese. By replacing milk protein with processed starch and replacing milk fat with vegetable fat, within the main component of cheese (which is milk protein, milk fat, water and others), you can make the base for plant-based cheese. Just replacement yet does not bring out cheese texture, and so there is room for trial and error.

7 Challenge for the Future

Why is the spread of plant-based alternative products in Japan delayed compared to abroad? It probably does not come from technical reasons but from the absence of a culture that requires specific ingredients from religious and philosophical beliefs. And so not only the fact of "alternativeness" but a quality that realizes a real flavor or other specific advantage is important in consumer acceptance. The recent advances in food additives and functionality are significant, and have been accepted by the consumers. More upgrades such as a cheese alternative that realizes the high-end cheese or cheese for room temperature consumption or functionality that is not possible in real cheese are sought. We would like to continue our endeavor in developing and spreading cheese alternative not as recognized as alternative but as a leading product.